Summarize this blog article with AI:

The manufacturing industry is at a critical inflection point. As factories embrace Industry 4.0, IoT, and smart automation, the underlying IT infrastructure must be as resilient and efficient as the production lines it supports. However, many IT leaders in the manufacturing sector are facing a new hurdle: the volatility of the virtualization market.

Following Broadcom’s acquisition of VMware, manufacturers are grappling with escalating licensing costs, uncertain support structures, and the complexity of managing traditional 3-tier architectures. The question is no longer if you should modernize your infrastructure, but how to do it without disrupting operations.

An IT manager from a large food manufacturing company (5,500 employees, ~300 VMs) told Ars Technica that their VMware support costs quadrupled after Broadcom stopped selling perpetual licenses and enforced bundled subscriptions with unwanted extras. They remarked, “They wouldn't sell us what we need.”

At Sangfor Technologies, we provide the answer. By replacing existing virtualization with Sangfor Hyperconverged Infrastructure (HCI), built on its hypervisor, Sangfor aSV, manufacturers can fully converge their data centers, ensuring high availability, simplified management, and significant cost reductions.

The Manufacturing IT Dilemma: Cost vs. Continuity

Manufacturing environments are unique. Unlike standard office environments, a server failure in a factory doesn't just mean email is down—it can mean production halts, supply chain delays, and significant revenue loss.

Traditional VMware-based virtualization solutions often trap manufacturers in a cycle of:

- High Total Cost of Ownership (TCO): Rising software licensing fees drain budgets that could be used for R&D or factory automation.

- Operational Silos: Managing separate storage, servers, and networking gear requires specialized skills and complex troubleshooting, slowing down response times.

- Migration Anxiety: The fear that moving away from established platforms will cause downtime prevents necessary upgrades.

The Sangfor Solution: Built for the Industrial Edge and Core

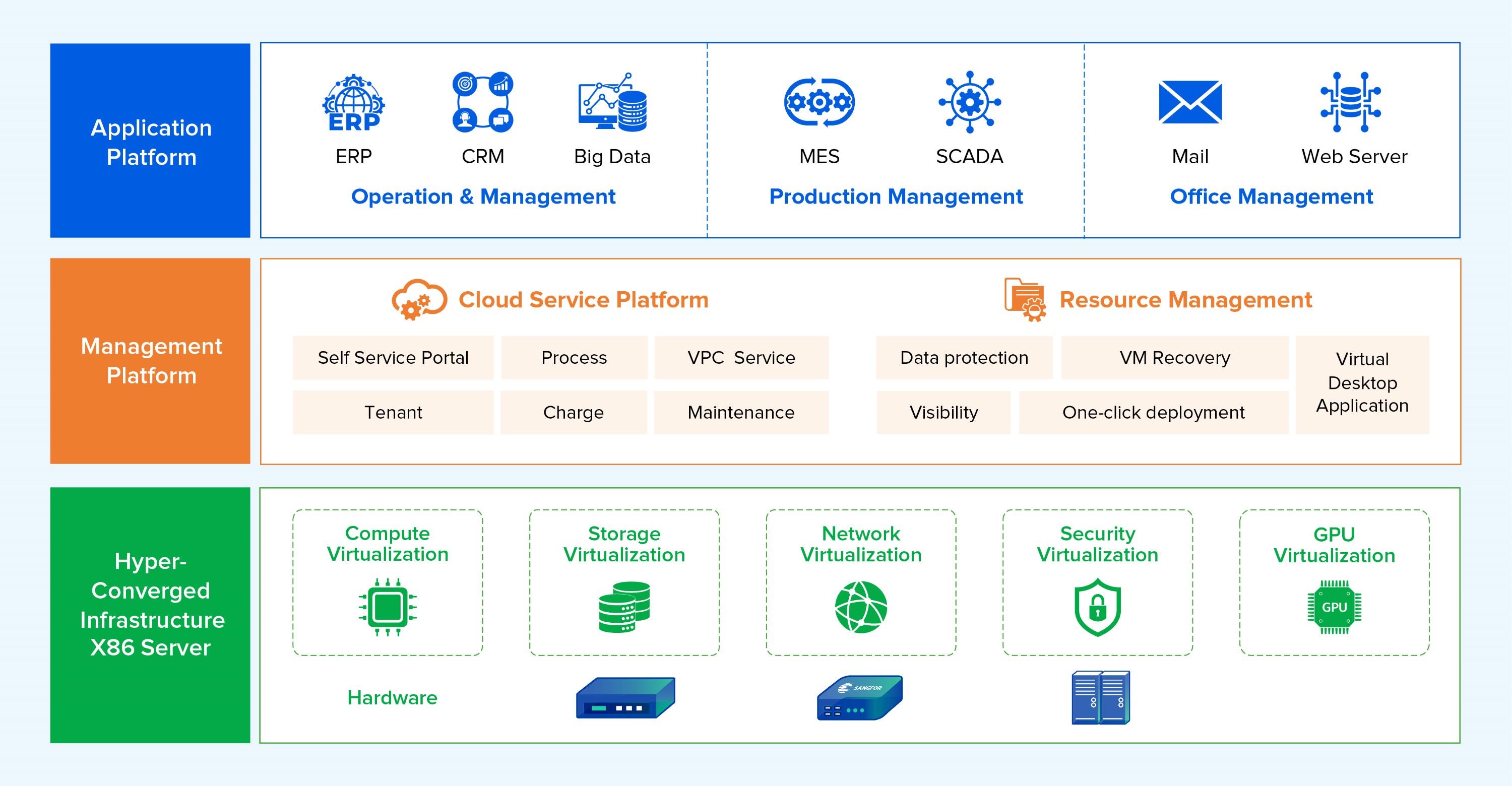

Sangfor HCI is not just a virtualization replacement; it is an enterprise cloud computing platform built on business-centric architecture. It consolidates compute, storage, networking, and security into a single software stack, running on commodity hardware.

Here is why Sangfor HCI is the superior choice for the manufacturing sector:

1. Seamless VMware Migration with Minimal Downtime

Transitioning critical manufacturing applications (ERP, MES, SCADA) requires precision. Sangfor offers a dedicated VMware Alternative solution designed for a seamless and efficient migration. Our tools allow for the smooth transfer of workloads from existing platforms to Sangfor HCI, ensuring that your production data remains intact and your downtime is kept to an absolute minimum without interrupting business.

2. Built-In Security: Protecting the Smart Factory

Manufacturing is now the #1 target for ransomware. Sangfor addresses this through aSEC (Cloud Security Center), a centralized management platform that bridges the gap between infrastructure and security. Unlike traditional virtualization platforms that require third-party security add-ons, Sangfor HCI features native, built-in security.

- Kernel-Level Protection: Security is embedded directly into the hypervisor kernel, providing a defense layer that external solutions cannot match.

- Visualized Vulnerability Management: aSEC provides a "heat map" of your entire HCI environment, identifying which VMs have unpatched vulnerabilities or open ports.

- Micro-Segmentation & Quarantine: If a workstation on the factory floor is compromised, aSEC can automatically trigger a micro-segmentation policy, "fencing off" the infected VM to prevent it from reaching the core ERP or the backups.

3. Uncompromising Reliability and Disaster Recovery

In manufacturing, uptime is currency. Sangfor HCI includes robust Disaster Recovery Management capabilities ranging from CDP, active-passive DR and active-active stretched cluster. Equipped with HA 2.0, workloads are automatically migrated to healthy nodes before a hardware node fails, ensuring high availability for your mission-critical applications. This resilience safeguards your business against hardware failures that would otherwise stop the assembly line. While traditional VMware environments often require complex, third-party add-ons for disaster recovery, Sangfor integrates these features natively. This ensures that if one node or even an entire data center fails, the production line keeps moving without human intervention.

4. Simplified Operations for Lean IT Teams

Manufacturing IT teams are often lean, managing vast networks across multiple plant sites. Sangfor HCI simplifies this with a unified management console. You can manage your entire infrastructure, from the data center to the factory edge, from a single interface. This "What You See Is What You Get" management style reduces the complexity of operations, allowing generalist IT staff to manage complex infrastructure easily.

5. Future-Proofing with Hybrid Cloud Readiness

As manufacturers look toward the cloud for data analytics and AI, Sangfor HCI serves as the perfect foundation. It offers a Hybrid Cloud solution that simplifies and secures your cloud journey. Whether you are keeping sensitive production data on-premise while bursting to the cloud for analytics, or managing a multi-site environment, Sangfor provides the flexibility to scale as your factory grows.

Case Study: Why a Leading Cookware Manufacturer in Thailand Made the Switch

The Challenge: A world‑leading cookware manufacturer with massive international customers base was struggling with increasing complexity and high maintenance costs in their existing VMware and physical server environment. They needed a platform that could handle the high I/O demands of their ERP system while ensuring 99.99% uptime.

The Solution: By migrating to Sangfor HCI, the company consolidated their infrastructure into a streamlined, high-performance cluster.

Results:

- 50% Reduction in Footprint: Reduced data center space and cooling costs.

- Enhanced Reliability: The integration of HA (High Availability) and CDP (Continuous Data Protection) ensured that their production data was protected against both hardware failure and human error.

- Simplified Management: The IT team could now manage compute, storage, and security from a single interface, allowing them to focus on digitalizing their production processes rather than managing hardware.

Industry Recognition You Can Trust

Switching infrastructure providers is a major decision, but you are in safe hands. Sangfor is a globally recognized leader in IT infrastructure:

- Gartner® Recognition: Sangfor is featured as a Sample Vendor for VMware Alternative in the Gartner® A Guide to Choosing a VMware Alternative and recognized as a Representative Vendor in the 2025 Gartner® Market Guide for Server Virtualization Platforms.

- Top Ratings: We received Top Ratings in the Gartner® Peer Insights™ 'Voice of the Customer' for Full-Stack HCIS.

- Global Reach: Serving over 27,000 cloud customers worldwide and helping 12,000+ organizations successfully migrate from VMware to Sangfor.

Conclusion: Elevate Your Strategy Beyond VMware

The manufacturing sector demands efficiency, reliability, and cost-effectiveness. Continuing to pay a premium for virtualization that adds complexity no longer makes business sense.

Sangfor HCI offers a path to a modern, software-defined data center that lowers costs, simplifies management, and keeps your production lines running smoothly. Unlock future-ready virtualization with minimal downtime and join the industrial leaders who have already made the switch.

Ready to benchmark your current costs against Sangfor HCI?

Contact Us today to speak with a manufacturing infrastructure specialist.